Summary

Process maturity: Stable

D1 having small size cell (SA5) exhibits stable switching. However, the instability exhibited in larger cell (SA60) can be avoided by introducing Cr barrier layer (D2).

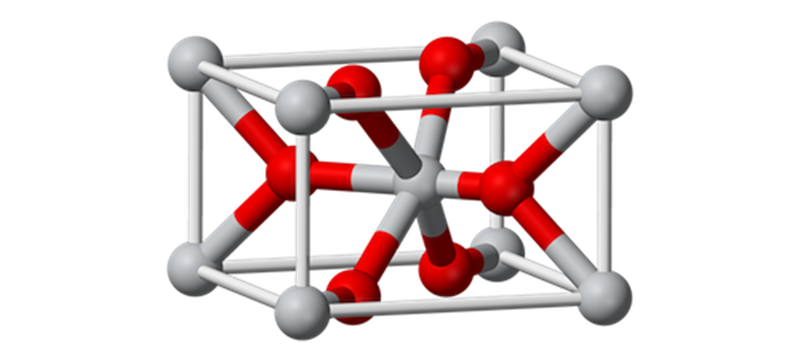

Active layer fabrication Data

|

Fabrication method: |

Magnetron sputtering |

|

Tool(s) used: |

Angstrom |

|

Main fabrication params: |

Ar:O₂ (2/1) ratio and flows (30 sccm); temperature (assumed RT if not specified); power (30 W); pressure (10 mTorr). |

|

Recipe |

Ar:O₂ |

Temp |

Comments |

|

ZnO_7_10mT_50 |

20:10 |

25°C |

Thickness 60 nm. |

Electrode configuration

|

Top |

Bottom |

Tool |

Comments |

|

Pt/Ag (10/30 nm) |

Pt/Ti (25/50 nm) |

LAB |

Standard recipe. High pristine resistance (D1) |

|

Pt/Ag/Cr (10/30/7 nm) |

Pt/Ti (25/50 nm) |

LAB |

Standard recipe. High pristine resistance (D2) |

Indicative data

|

|

D1 Measurement: Formed devices (Vform ~1.3V); I-V characteristic; Reset voltage -2V; Complianceless; Device stack: Pt/Ag/ZnO/Pt 10/30/60/25 (in nm, top to bottom); SA5. Active layer recipe: ZnO_7_10mT_50 Comment: Device yield ~70%, stable DC endurance (ratio >102).

D1 Measurement: Formed devices (Vfrom ~1.3); I-V characteristic; Reset voltage -1.5V; Compliance 100μA . Device stack: Pt/Ag/ZnO/Pt 10/30/60/25 (in nm, top to bottom); SA5. Active layer recipe: ZnO_7_10mT_50 Comment: Device yield ~70%, stable DC endurance (ratio >10).

D2 Measurement: Formed devices (Vfrom ~2V); I-V characteristic; Reset voltage -1.5V; Compliance 1 mA. Device stack: Pt/Ag/Cr/ZnO/Pt 10/30/7/60/25 (in nm, top to bottom); SA60. Active layer recipe: ZnO_7_10mT_50 Comment: Device yield ~70%, stable DC endurance (ratio >10). |